If you’ve ever tried to buy glazed leather for your factory or workshop, you know it’s not as simple as it sounds. Prices vary, quality is all over the place, and finding the right supplier can feel like a guessing game.

This guide breaks it all down in plain language what glazed leather actually is, how to tell good from bad, where to source it, and how to avoid common mistakes. Whether you’re running a small setup or managing large-scale production, you’ll walk away knowing how to get the best material without wasting time or money..

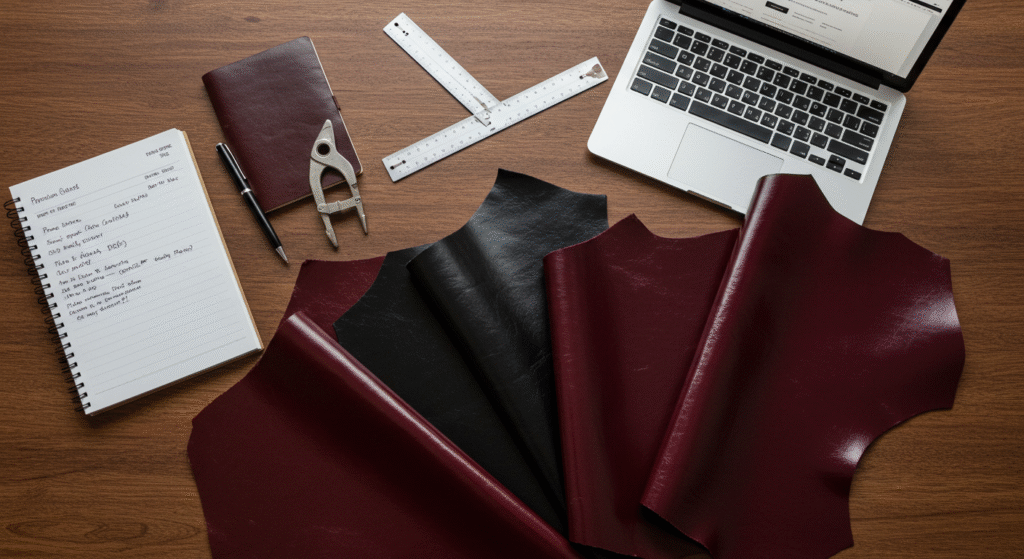

Understanding Premium Glazed Leather

What Makes Leather ‘Premium’ and ‘Glazed’?

Great glazed leather starts with top-tier hides. Full-grain leather, cut from the outer layer of cowhide, is the strongest, natural, and free of scars or marks. Top-grain’s a close second, lightly smoothed out but still solid. These hides are hand-picked to avoid flaws, perfect for high-end manufacturing.

The “glazed” part happens in the tannery. After tanning, the leather gets polished or coated with a clear layer, giving it a shiny, water-resistant finish that screams class. You’ve got two main options: aniline glazed, which keeps the leather’s natural texture for a soft, real-deal feel (think luxury bags), and pigmented glazed, with a tougher, scratch-proof coating for heavy use like car seats. Aniline’s gorgeous but needs babying; pigmented’s built to take a beating. Pick based on what you’re making fashion stuff or furniture.

Key Characteristics to Look For

When hunting for glazed leather, keep these must-haves in mind:

- Thickness: Shoot for 1.2-1.5mm to balance bendiness and strength.

- Tensile Strength: Make sure it won’t tear when stretched, key for upholstery or shoes.

- Color Fastness: Check that colors stay bright, even in sunlight.

- Certifications: Look for REACH compliance (EU safety rules) or Leather Working Group (LWG) ratings to know it’s eco-friendly.

Eyeball the leather, too it should have a steady shine and feel smooth. Grab a sample swatch and test it in your setup to make sure it’s up to snuff.

The Leather Tannery and Manufacturing Process

How Glazed Leather is Produced in Tanneries

Turning raw hides into glazed leather is a real craft. Here’s how it goes down:

- Prep Work: Hides get soaked to clean off dirt, hair, and salt. Then liming softens them up, scraping away hair and fat.

- Tanning: This locks in the hide’s durability and flexibility. Chrome tanning uses chemicals for a soft, colorful result, while vegetable tanning, with stuff like mimosa bark, is slower but kinder to the planet big with eco-conscious brands.

- Dyeing and Oiling: Dyes add bold colors, and oils keep the leather soft. Semi-finished crust leather’s a favorite for folks who want to tweak colors later.

- Glazing: The final step’s where the shine happens. Hides are buffed with rollers or sprayed with a glossy coating, sometimes using heated plates for a mirror-like finish.

Tanneries deal with headaches like chrome tanning’s chemical runoff. Lots of places, especially in Pakistan and Europe, are switching to recycled water systems and plant-based glazes to cut down on harm. Vegetable-tanned glazed leather’s getting hot for its green cred.

Integrating Glazed Leather into Your Manufacturing Workflow

Ready to work with glazed leather? Here’s the game plan:

- Cutting and Patterning: Use CAD software to map out cuts and waste less. Glazed leather shows every mistake, so be precise. Laser cutters give clean edges.

- Stitching: Go for heavy-duty machines with nylon threads. Don’t stitch too tight it can crack the shiny finish.

- Finishing: Pick glues that won’t mess up the shine. Test sealants to keep that glossy look.

- Quality Checks: Run abrasion tests (like Martindale) and flex tests to make sure the leather holds up.

Hot Tip: Keep glazed leather in 40-60% humidity to stop cracks or fading before you start working with it.

Best Practices for Sourcing Premium Glazed Leather

Top Global Suppliers and Regions for Glazed Leather

Finding a solid supplier is everything. Here’s where to look, with a nod to a standout:

- Pakistan (Kasur): Akram Tannery’s a top player, offering LWG-certified vegetable-tanned and finished glazed leather, shipped to the USA, UK, UAE, and more. Our hides, featured at APLF 2022 Dubai, are great for fancy bags, shoes, and car seats. Check out AkramTannery.com for samples.

- Italy (Santa Croce): Famous for vegetable-tanned glazed leather, with tanneries like Conceria La Perla Azzurra supplying big-name brands. Top quality, but it’ll cost you.

- Brazil: Big on chrome-tanned leather, with JBS Couros pumping out tons for car interiors.

- India: Budget-friendly, with places like Farida Group making leather for shoes. Quality’s hit-or-miss, so check carefully.

- USA: Horween Leather in Chicago’s great for custom glazed finishes, perfect for small, high-end batches.

How to Source:

- Straight from Tanneries: Best for custom or big orders (1,000+ sq ft). You’ll save money and know exactly where your leather’s coming from.

- Wholesalers: Quick for smaller batches, but you might not get top quality. Test samples first.

- Start Small: Grab 50-100 sq ft to try out before going all-in on a big order.

Evaluating Supplier Quality and Reliability

Here’s a checklist to size up suppliers:

- Certifications: ISO 9001 for quality, LWG Gold for green practices.

- Traceability: They should track hides from farm to tannery. Blockchain’s a big help here.

- Sample Testing: Check swatches for even thickness, steady color, and tough glaze.

- Reputation: Peek at trade forums or event buzz, like feedback from Pakistan Mega Leather Show 2023.

Watch Out For:

- Spotty dyeing or streaky shine.

- Hides with scars or weak spots.

- Suppliers who dodge questions about their tanning process.

Sustainable and Ethical Sourcing Tips

Going green’s a big deal these days. Here’s how to source smart:

- Certifications: Stick with LWG Gold-rated tanneries for eco-friendly standards.

- Green Practices: Look for plant-based glazes and water recycling. Vegetable-tanned glazed leather’s a crowd-pleaser for sustainability.

- Traceability: Make sure suppliers verify humane animal treatment and fair worker conditions.

- What’s Hot: Vegetable-tanned leather’s booming, especially for brands that care about the planet.

Case Study: A handbag maker in the UAE teamed up with Akram Tannery in 2023 for vegetable-tanned glazed leather. By shouting out their eco-friendly sourcing, they bumped up sales by 20% in a year.

Common Challenges and Solutions in Sourcing

Sourcing glazed leather can be tricky. Here’s how to handle the big issues:

- Supply Hiccups: Port delays or hide shortages (like when cattle supplies dip) can mess up your schedule. Fix: Pick suppliers with multiple sources and flexible delivery.

- Price Swings: Hide costs go up and down with demand. Fix: Lock in prices with futures contracts or work with suppliers offering steady bulk deals.

- Fake Goods: Some pass off cheap leather as premium. Fix: Go for suppliers with blockchain to prove their hides are legit.

- Tough Regulations: New chemical rules can limit chrome-tanned leather. Fix: Switch to vegetable-tanned glazed leather that meets REACH standards.

Real-World Story: A UK furniture company hit snags with an Indian supplier’s delays in 2024. By switching to a dependable Pakistani supplier, they cut downtime by 30% and kept production on track.

Conclusion

Finding premium glazed leather takes know-how and the right supplier. Start with high-quality hides, get the lowdown on tanning and glazing, and pick partners with LWG certifications and clear sourcing practices. Tackle issues like price jumps or supply delays with smart moves like spreading out your suppliers. Whether you’re crafting luxe goods or car upholstery, great glazed leather makes your brand stand out.

Ready to get started? Head to AkramTannery.com to grab samples of our vegetable-tanned or finished glazed leather, or reach out to talk bulk orders. Watch our factory tour video for a peek at our Kasur setup, and check out our guides on tanning and eco-friendly sourcing for more pointers.

FAQ Section

Frequently Asked Questions About Sourcing Premium Glazed Leather

Q1: What’s the difference between glazed and polished leather?

Glazed leather’s got a protective coating for shine and toughness, while polished leather’s just buffed for a natural look.

Q2: How much does premium glazed leather cost per square foot?

You’re looking at $3-6 for chrome-tanned, $6-10 for vegetable-tanned. Get quotes based on how much you need.

Q3: Are there eco-friendly options for glazed leather?

Yup! Vegetable-tanned glazed leather, with LWG certification, uses natural tannins and green glazes.

Q4: How to check a supplier’s quality?

Ask for samples, look for ISO 9001 or LWG certifications, and test for thickness and colour staying power.

Q5: What tools work best with glazed leather?

Use CAD for cutting, heavy-duty sewing machines with nylon threads, and Martindale testers to check quality.